Now, with the value addition in casting foundries, machining plays a vital role to get better solutions for our customer.

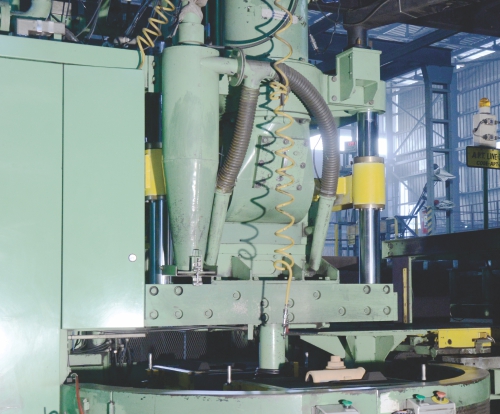

Along with the standard machines, Hi-Mac have specialized machines as well to provide customized solutions.

Glimpse of the processes are as below…

Hi-Mac has always been working best to provide samples on time. Out inhouse facilities helps for the same...

Design

Tooling

Hanger type

Tumblast Type

Hi-Mac is dedicated to quality requirements of our premium customer. We use different types of *packing materials like Wooden, Corrugated, Polythene, etc for avoiding part damage and protection from atmosphere.

*Mutually agreed with customer